Hi Gents.

I haven't been on the forum at all for the past couple of months. No specific reason - just needed a bit of a break I guess. Anyway, things haven't been standing still during my absence - forward is the only motion we can allow

I see I have a number of PMs. I will go through them and respond to everyone within the next couple of days - my apologies if you sent an urgent message and the response is really late :-[

A quick update on what's been happening:

1. I have been spending quite a bit of time learning the art of composites - specifically carbon fiber and mold making. Messed around with everything from wet layups by hand to vacuum infusion techniques. Lots of fun and very itchy work. Fortunately you actually get used to the itch so it doesn't bother you so much after a while.

2. Stripped my hi-fi room pretty much bare. I am doing some room treatment and am building a false wall on one end for damping including integrated bass traps. That project is taking very long, mostly because I am also busy with too many other things at the same time. Completion time is unknown at this point, so music listening is limited to headphones these days.

3. Been building the largest cabinets I have ever made for some subwoofer use in my system.

4. Added to my metal working tools by purchasing a small milling machine and learning how to use it.

Text is always a bit boring, so let's get into some picture updates:

This is the pile of plywood I bought to build the subs out of. 10 sheets of 32mm BB grade pine plywood, cut in half so 20 sheets:

This is the total height of that pile of wood:

Internal brace:

Baffle:

Baffle being glued to the brace:

More bracing being glued in. Just for reference - the workbench the cabinet is lying on is 2.35m long...

Large chamfer edges going on:

More bracing. With the back glued on (excluding drivers, etc) the damn cabinet is now so heavy that I can just barely lift the one edge off the table. How I am going to move this thing is beyond me, but I will figure something out.

Next I decided I wanted to make some nice ports using the composites skills I have been honing. This is a picture of the mold I made. The blue color is gel-coat resin.

Here I am performing the vacuum assisted resin infusion into the fabrics:

And this is the resulting part after demolding. I obviously still need to trim all the flash, etc off:

This is the new milling machine. With the vice and rotary table mounted it is just short of 400kg. Not large or heavy duty by any stretch of the imagination, but perfect for what I need to do:

This is the first serious job I did on the mill. I made a locking collar which sits on the spindle and gives me somewhere to grip on to when changing drill bits:

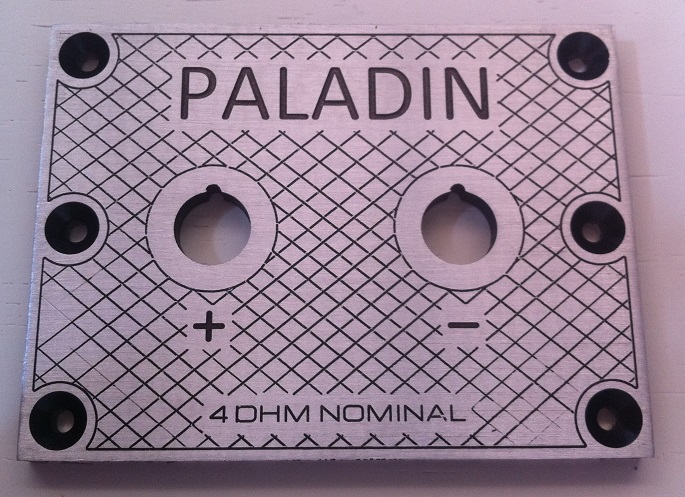

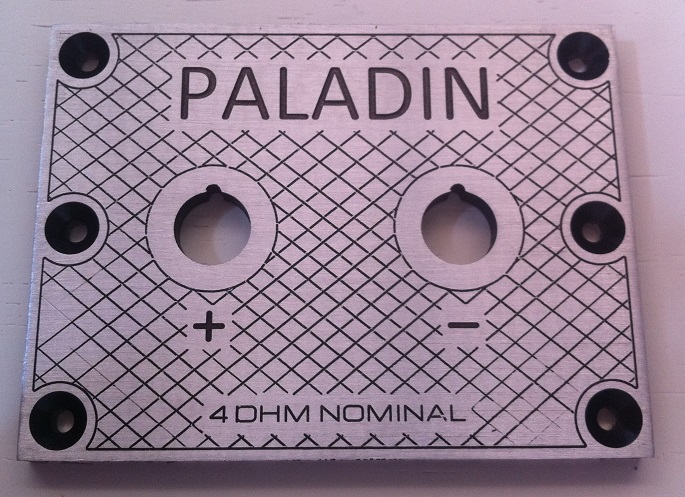

I have also been messing around with making some terminal plates for my speakers and subwoofers. Here is an example which includes milling, engraving, drilling, boring, brushing and some other processes. It's not perfect, but for a first attempt I think it looks ok.

Let me know what you think

Kind Regards,

Ian.

I haven't been on the forum at all for the past couple of months. No specific reason - just needed a bit of a break I guess. Anyway, things haven't been standing still during my absence - forward is the only motion we can allow

I see I have a number of PMs. I will go through them and respond to everyone within the next couple of days - my apologies if you sent an urgent message and the response is really late :-[

A quick update on what's been happening:

1. I have been spending quite a bit of time learning the art of composites - specifically carbon fiber and mold making. Messed around with everything from wet layups by hand to vacuum infusion techniques. Lots of fun and very itchy work. Fortunately you actually get used to the itch so it doesn't bother you so much after a while.

2. Stripped my hi-fi room pretty much bare. I am doing some room treatment and am building a false wall on one end for damping including integrated bass traps. That project is taking very long, mostly because I am also busy with too many other things at the same time. Completion time is unknown at this point, so music listening is limited to headphones these days.

3. Been building the largest cabinets I have ever made for some subwoofer use in my system.

4. Added to my metal working tools by purchasing a small milling machine and learning how to use it.

Text is always a bit boring, so let's get into some picture updates:

This is the pile of plywood I bought to build the subs out of. 10 sheets of 32mm BB grade pine plywood, cut in half so 20 sheets:

This is the total height of that pile of wood:

Internal brace:

Baffle:

Baffle being glued to the brace:

More bracing being glued in. Just for reference - the workbench the cabinet is lying on is 2.35m long...

Large chamfer edges going on:

More bracing. With the back glued on (excluding drivers, etc) the damn cabinet is now so heavy that I can just barely lift the one edge off the table. How I am going to move this thing is beyond me, but I will figure something out.

Next I decided I wanted to make some nice ports using the composites skills I have been honing. This is a picture of the mold I made. The blue color is gel-coat resin.

Here I am performing the vacuum assisted resin infusion into the fabrics:

And this is the resulting part after demolding. I obviously still need to trim all the flash, etc off:

This is the new milling machine. With the vice and rotary table mounted it is just short of 400kg. Not large or heavy duty by any stretch of the imagination, but perfect for what I need to do:

This is the first serious job I did on the mill. I made a locking collar which sits on the spindle and gives me somewhere to grip on to when changing drill bits:

I have also been messing around with making some terminal plates for my speakers and subwoofers. Here is an example which includes milling, engraving, drilling, boring, brushing and some other processes. It's not perfect, but for a first attempt I think it looks ok.

Let me know what you think

Kind Regards,

Ian.