Hi Everyone,

After all the snide chirps and comments (mainly from my brothers, [member=18550]El Sid[/member] and [member=22015]Nchebe[/member] ) about my cheap-ass sub build in this post; https://www.avforums.co.za/index.php/topic,76737.0.html

I decided to build a second experimental sub that?s going to be the basis for my final build. El Sid and Nchebe are from the critical listening crowd, whilst I?m from the home theatre crowd so when they saw my first sub build, the chirps started flying. Things like? Which one?s the piano?? and ?I thought you were building a box, not an infinite baffle? and ?Cool fort you?ve built for the kids? and ?Your wife?s gonna love the walk-in-closet?.

They laugh at my sub, I laugh at their sound bars! My wife accepted the sub, but wasn?t overly happy with it, so I had to make a plan. I was unexpectedly blown away by the performance of the cheap-ass sub; however it did have its limitations. The Xmax of the driver was around 5mm, so it bottomed out when driven hard or during large program peaks and being a PA woofer, it couldn?t tune really low.

After reading other DIY builds on this site and seeing the suggestions, I decided to get a couple of 15? Targa Viper drivers. I really struggled to find anyone who had stock of them until I finally found a pair at a car audio shop in the Hillfox China Mall. Apparently they aren?t being made anymore. :sd:

This thing is a beast!

I removed the logo from the dustcap using turpentine as suggested by [member=17355]Mongoose[/member] in this post: http://www.avforums.co.za/index.php?topic=52100.0 (Obligatory shoe shot included)

This is a R5 coin to show the dimensions of the surround, voice coil port and magnet.

This thing has a massive Xmax, around 15mm, should easily handle anything I can throw at it. I wired the DVC in series for 8 ohms, this way I could run both subs in parallel off a single channel monobloc amp and ensure the amp would still drive an effective 4 ohm load.

Start of the build, this box is 450mmW x 450mmD x 590mmH giving approx 120L. The old box is 520mmW x 590mmD x 560mmH giving approx 170L. The build uses 16mm chipboard from old cupboard doors, certainly not ideal material, but seeing as it?s not going to be the final build, it?ll be good enough. By building it narrower, shallower and taller, it uses less floor space and fits into tight spaces easier; hopefully that'll score some WAF points. The only place the old sub fits is under the piano.

Bracing panels

Dry fit

The baffle is one of the test baffles from the old sub. Glued in M6 T-nuts for the driver and filled in the old reflex port holes.

Drilled air gaps in all the bracing panels and glued the panels in. The bigger holes next to the vertical brace are for the 75mm PVC pipes that are going to be used for the reflex ports. The ports are down firing for two reasons, I can use longer pipes as the box is taller than it is deep or wide and also the ports will not be seen so that'll hopefully add to the WAF. The area of the openings of the two 75mm PVC pipes is close to the area of a single 110mm PVC pipe (8835mm squared vs 9503mm squared). DIY tip: If at all possible, use a drill press when drilling holes with a hole saw. Set the drill press to low speed and high torque, it cuts much easier than doing it freehand as the bit is always perpendicular to the board.

Holes for the PVC pipes.

Pipes dry fit test.

The two small holes near the top middle are for the cable binding post. The cable also attaches at the bottom so that the cable doesn?t get in the way of walls or other objects and thus can be hidden more easily. Yet another WAF point.

Bought a router for this build. I can?t believe I haven?t bought one up until now. It makes building speaker boxes sooo much easier! From cutting the hole and recess for the driver to rounding the edges of the box and flaring the ports.

Baffle dry fit test. Cut the recess for the driver with the router. The hole was already cut with a jigsaw from the previous sub build. I didn?t have the router at the time.

Driver test fit in the recess, there was about 1mm gap between the driver and edge of recess.

Smoothed the edges of the box using a ?? roundover bit.

Test fit feet to the box.

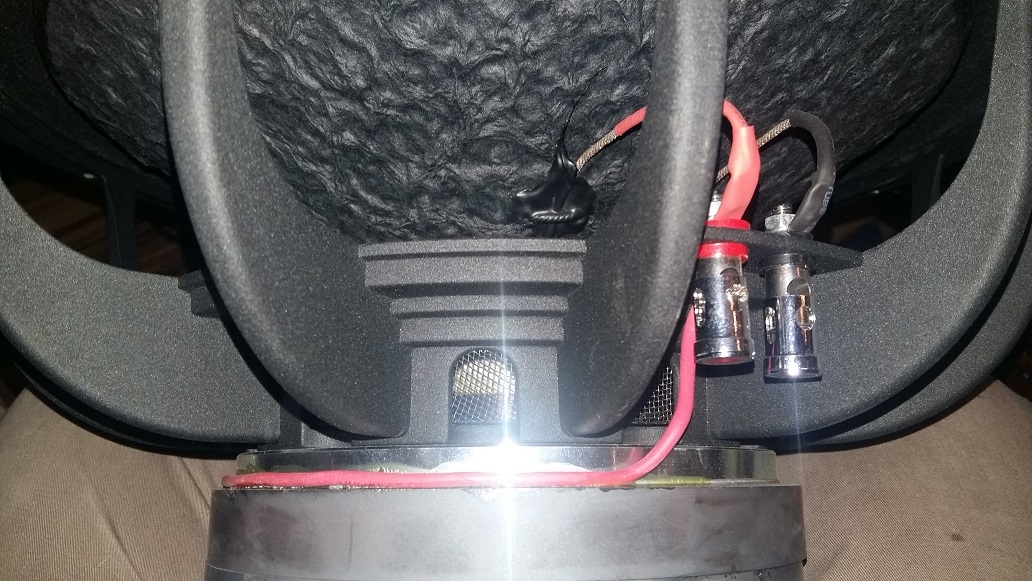

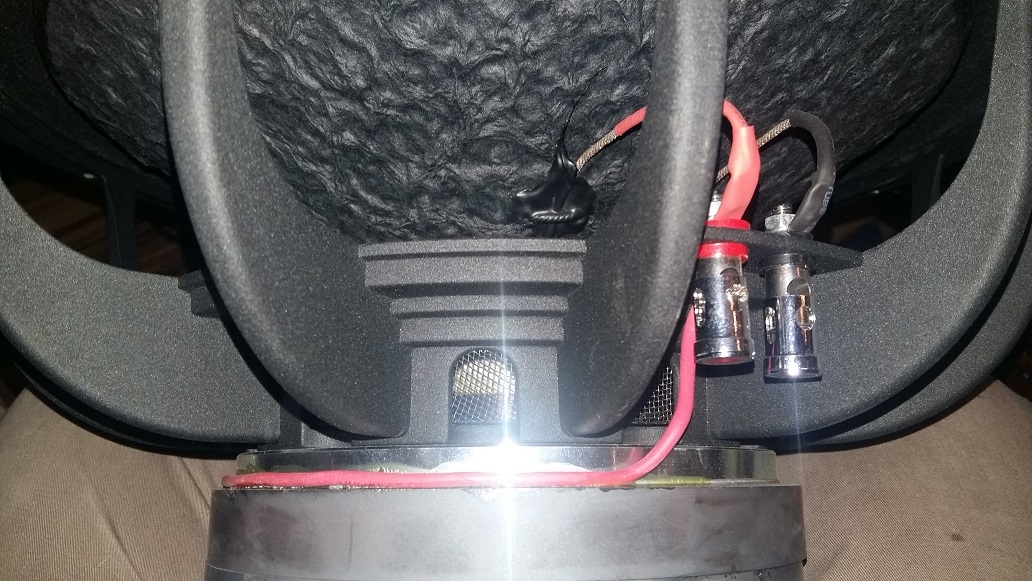

Installed binding post and speaker wire.

Glued dog blanket to the interior walls and baffle.

Flared the ports using a ?? roundover bit. Really chuffed at how it turned out. (Sorry, couldn?t help it!)

Used wood filler to fill the edges and then sanded them smooth.

Glued and screwed on the baffle.

Used a few pots of wood filler and spent a LONG time sanding the box to get the uneven edges smooth and then fitted the driver for testing. Looks like something out of a piss-poor auto-body repair shop. Of course I blame the tools I?ve collected over the years; it?s DEFINITELY not because of me!

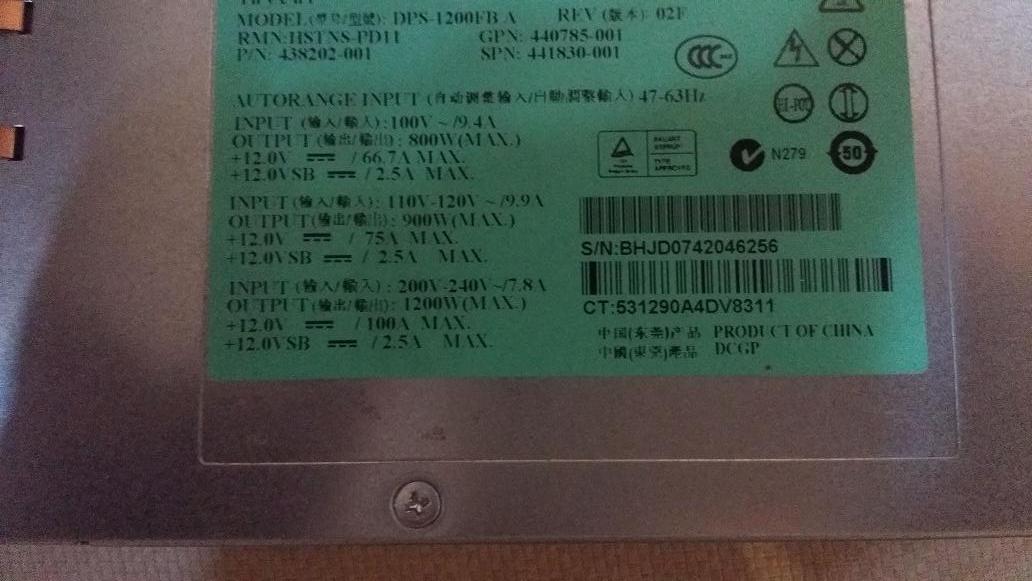

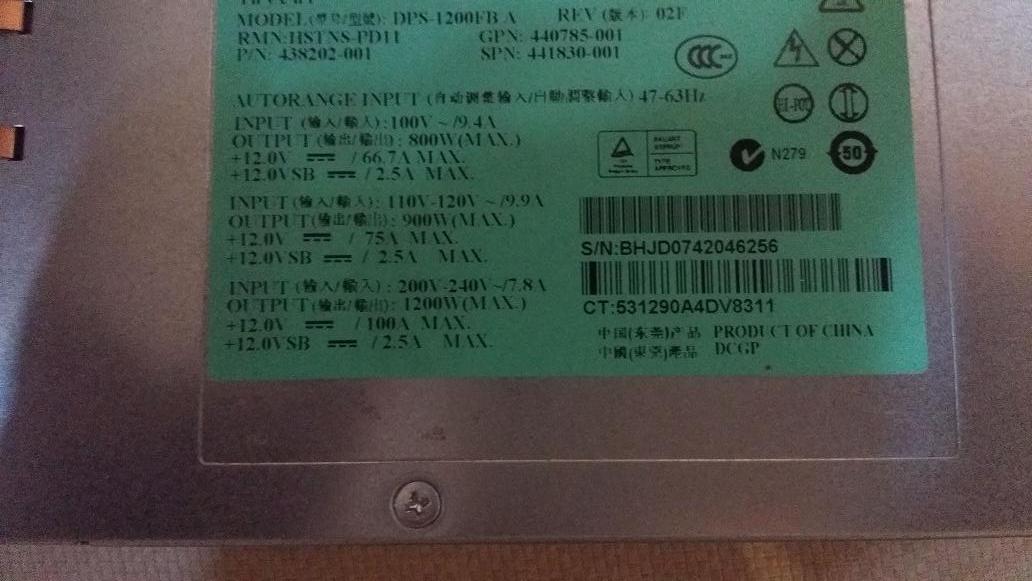

Bought an Ice Power Monobloc amp for R1300 and an HP server power supply from Aliexpress for $20 that?s rated at 1.2KW!! Yup, that tiny little silver block can pump out 100A at 12V. It uses synchronous rectification, so it?s ~95% efficient. The amp says it?s 11 billion jigawatts, so I have no idea what it?s true RMS power rating is. At some stage I?ll put a 50Hz sine wave tone through it and measure the output voltage until it clips and then calculate the true power rating with a 4 ohm and an 8 ohm load.

HP 1200W PSU. I have to do a few modifications to it to make it switch on and off easily without being connected to an actual server and also to up the voltage to around 13.5V for a bit of extra power. I?m using a bog standard 450W PC power supply in the meantime.

Did a couple of quick tests to check it?s performance. #$%& me!!! This thing is stupendous! Ridiculously loud and super low. Definitely feel the thump in your chest during big explosions etc. Reflex ports working well too, no discernible chuffing at uncomfortably loud levels. If I pushed it to the max it might chuff, but I?m unlikely to ever listen to it that loud. Even at moderate levels, it rattles the windows in the upstairs bedrooms.

Once I had finished the tests, it was time to paint it. Normally I?d paint it a nice matt black, but because this is the WAF woofer, it was painted white.

White undercoat applied.

Four coats of Grecian White acrylic later. DIY tip no.2: I painted this box with a normal brush and my first sub build with a small foam roller. I found the foam roller is a much better tool to use for this. It?s faster for starters and it puts down a much more even coat of paint.

Finished!! In hindsight, I should?ve painted the driver recess on the baffle black, as the foam seal around the rear edge of the driver pops out a tiny bit and makes the driver look a bit uneven in places. I?ll sort it out at some stage.

The amp in all it?s blue bling glory. Wife loves this, NOT! Definitely going to take the amp apart and remove the blue LEDs. My wife wants to glue laser cut MDF Moroccan patterns to the sides of the box and paint it nicely with a patina effect and then put a table top on top of the box to convert it into a side table. We?re going to experiment with this box and then draw up plans for the final build. I?ve got a few sheets of 32mm MDF lined up already, however, this time I?m going to get the boards professionally cut and CNC?d, it?ll save so much time and effort. The wood filler-ing and sanding to fix the stuff-ups I made, took ages to do. If my skills were up to the task when I first cut the boards, I would?ve saved a lot of time and hassle.

I?m once again gobsmacked by the performance of a DIY sub. For not much more than an entry level 12? commercial sub, you can build a thunderous 15? monster that simply destroys many commercial subs. I?ve currently got two 12? AR subs that have served me very well over the years, but this 15? Targa driver is simply in another league. It?s deeper, meatier and louder. When it?s uncomfortably loud, it?s not even close to Xmax. I sent the poor 450W power supply into over current protection during the final battle scene in Aquaman yet the driver was hardly breaking a sweat. If you?ve got the skills and willingness, I wholeheartedly recommend attempting a DIY sub build. It?s really rewarding after putting in all those hours to hear how good it sounds. It?s taken me about four months to finish this build, only being able to grab an hour here and there to work on it due to real life getting in the way, but you can?t wipe the smile from my face when it?s blasting away.

Edit: Fixed images, using Imgur rather than Photobucket.

After all the snide chirps and comments (mainly from my brothers, [member=18550]El Sid[/member] and [member=22015]Nchebe[/member] ) about my cheap-ass sub build in this post; https://www.avforums.co.za/index.php/topic,76737.0.html

I decided to build a second experimental sub that?s going to be the basis for my final build. El Sid and Nchebe are from the critical listening crowd, whilst I?m from the home theatre crowd so when they saw my first sub build, the chirps started flying. Things like? Which one?s the piano?? and ?I thought you were building a box, not an infinite baffle? and ?Cool fort you?ve built for the kids? and ?Your wife?s gonna love the walk-in-closet?.

They laugh at my sub, I laugh at their sound bars! My wife accepted the sub, but wasn?t overly happy with it, so I had to make a plan. I was unexpectedly blown away by the performance of the cheap-ass sub; however it did have its limitations. The Xmax of the driver was around 5mm, so it bottomed out when driven hard or during large program peaks and being a PA woofer, it couldn?t tune really low.

After reading other DIY builds on this site and seeing the suggestions, I decided to get a couple of 15? Targa Viper drivers. I really struggled to find anyone who had stock of them until I finally found a pair at a car audio shop in the Hillfox China Mall. Apparently they aren?t being made anymore. :sd:

This thing is a beast!

I removed the logo from the dustcap using turpentine as suggested by [member=17355]Mongoose[/member] in this post: http://www.avforums.co.za/index.php?topic=52100.0 (Obligatory shoe shot included)

This is a R5 coin to show the dimensions of the surround, voice coil port and magnet.

This thing has a massive Xmax, around 15mm, should easily handle anything I can throw at it. I wired the DVC in series for 8 ohms, this way I could run both subs in parallel off a single channel monobloc amp and ensure the amp would still drive an effective 4 ohm load.

Start of the build, this box is 450mmW x 450mmD x 590mmH giving approx 120L. The old box is 520mmW x 590mmD x 560mmH giving approx 170L. The build uses 16mm chipboard from old cupboard doors, certainly not ideal material, but seeing as it?s not going to be the final build, it?ll be good enough. By building it narrower, shallower and taller, it uses less floor space and fits into tight spaces easier; hopefully that'll score some WAF points. The only place the old sub fits is under the piano.

Bracing panels

Dry fit

The baffle is one of the test baffles from the old sub. Glued in M6 T-nuts for the driver and filled in the old reflex port holes.

Drilled air gaps in all the bracing panels and glued the panels in. The bigger holes next to the vertical brace are for the 75mm PVC pipes that are going to be used for the reflex ports. The ports are down firing for two reasons, I can use longer pipes as the box is taller than it is deep or wide and also the ports will not be seen so that'll hopefully add to the WAF. The area of the openings of the two 75mm PVC pipes is close to the area of a single 110mm PVC pipe (8835mm squared vs 9503mm squared). DIY tip: If at all possible, use a drill press when drilling holes with a hole saw. Set the drill press to low speed and high torque, it cuts much easier than doing it freehand as the bit is always perpendicular to the board.

Holes for the PVC pipes.

Pipes dry fit test.

The two small holes near the top middle are for the cable binding post. The cable also attaches at the bottom so that the cable doesn?t get in the way of walls or other objects and thus can be hidden more easily. Yet another WAF point.

Bought a router for this build. I can?t believe I haven?t bought one up until now. It makes building speaker boxes sooo much easier! From cutting the hole and recess for the driver to rounding the edges of the box and flaring the ports.

Baffle dry fit test. Cut the recess for the driver with the router. The hole was already cut with a jigsaw from the previous sub build. I didn?t have the router at the time.

Driver test fit in the recess, there was about 1mm gap between the driver and edge of recess.

Smoothed the edges of the box using a ?? roundover bit.

Test fit feet to the box.

Installed binding post and speaker wire.

Glued dog blanket to the interior walls and baffle.

Flared the ports using a ?? roundover bit. Really chuffed at how it turned out. (Sorry, couldn?t help it!)

Used wood filler to fill the edges and then sanded them smooth.

Glued and screwed on the baffle.

Used a few pots of wood filler and spent a LONG time sanding the box to get the uneven edges smooth and then fitted the driver for testing. Looks like something out of a piss-poor auto-body repair shop. Of course I blame the tools I?ve collected over the years; it?s DEFINITELY not because of me!

Bought an Ice Power Monobloc amp for R1300 and an HP server power supply from Aliexpress for $20 that?s rated at 1.2KW!! Yup, that tiny little silver block can pump out 100A at 12V. It uses synchronous rectification, so it?s ~95% efficient. The amp says it?s 11 billion jigawatts, so I have no idea what it?s true RMS power rating is. At some stage I?ll put a 50Hz sine wave tone through it and measure the output voltage until it clips and then calculate the true power rating with a 4 ohm and an 8 ohm load.

HP 1200W PSU. I have to do a few modifications to it to make it switch on and off easily without being connected to an actual server and also to up the voltage to around 13.5V for a bit of extra power. I?m using a bog standard 450W PC power supply in the meantime.

Did a couple of quick tests to check it?s performance. #$%& me!!! This thing is stupendous! Ridiculously loud and super low. Definitely feel the thump in your chest during big explosions etc. Reflex ports working well too, no discernible chuffing at uncomfortably loud levels. If I pushed it to the max it might chuff, but I?m unlikely to ever listen to it that loud. Even at moderate levels, it rattles the windows in the upstairs bedrooms.

Once I had finished the tests, it was time to paint it. Normally I?d paint it a nice matt black, but because this is the WAF woofer, it was painted white.

White undercoat applied.

Four coats of Grecian White acrylic later. DIY tip no.2: I painted this box with a normal brush and my first sub build with a small foam roller. I found the foam roller is a much better tool to use for this. It?s faster for starters and it puts down a much more even coat of paint.

Finished!! In hindsight, I should?ve painted the driver recess on the baffle black, as the foam seal around the rear edge of the driver pops out a tiny bit and makes the driver look a bit uneven in places. I?ll sort it out at some stage.

The amp in all it?s blue bling glory. Wife loves this, NOT! Definitely going to take the amp apart and remove the blue LEDs. My wife wants to glue laser cut MDF Moroccan patterns to the sides of the box and paint it nicely with a patina effect and then put a table top on top of the box to convert it into a side table. We?re going to experiment with this box and then draw up plans for the final build. I?ve got a few sheets of 32mm MDF lined up already, however, this time I?m going to get the boards professionally cut and CNC?d, it?ll save so much time and effort. The wood filler-ing and sanding to fix the stuff-ups I made, took ages to do. If my skills were up to the task when I first cut the boards, I would?ve saved a lot of time and hassle.

I?m once again gobsmacked by the performance of a DIY sub. For not much more than an entry level 12? commercial sub, you can build a thunderous 15? monster that simply destroys many commercial subs. I?ve currently got two 12? AR subs that have served me very well over the years, but this 15? Targa driver is simply in another league. It?s deeper, meatier and louder. When it?s uncomfortably loud, it?s not even close to Xmax. I sent the poor 450W power supply into over current protection during the final battle scene in Aquaman yet the driver was hardly breaking a sweat. If you?ve got the skills and willingness, I wholeheartedly recommend attempting a DIY sub build. It?s really rewarding after putting in all those hours to hear how good it sounds. It?s taken me about four months to finish this build, only being able to grab an hour here and there to work on it due to real life getting in the way, but you can?t wipe the smile from my face when it?s blasting away.

Edit: Fixed images, using Imgur rather than Photobucket.